- About Us

-

Services

-

Lead Management Solution

Auto Capturing, nurturing, and converting potential customer leads.

-

AMC/ Warranty Management

Manage AMC contracts, track service requests, ensure timely renewals.

-

Service Ticket management

Tracks, resolves, manages issues, and gathers customer feedback.

-

Purchase Management

Manage purchases, expenses, vendors, and POs efficiently with CRM.

-

Order management solution

Manages order lifecycle from placement to delivery completion.

-

Invoicing Management

Generates invoices and manages sales transactions and records efficiently.

-

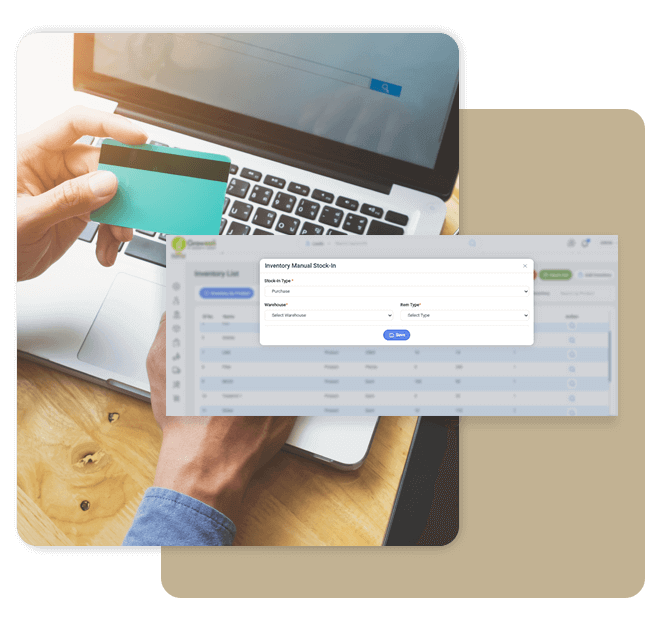

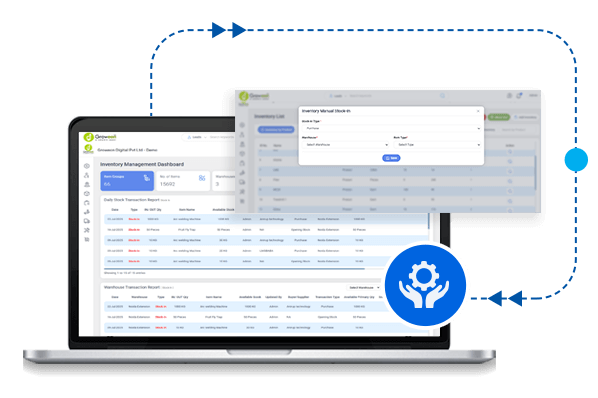

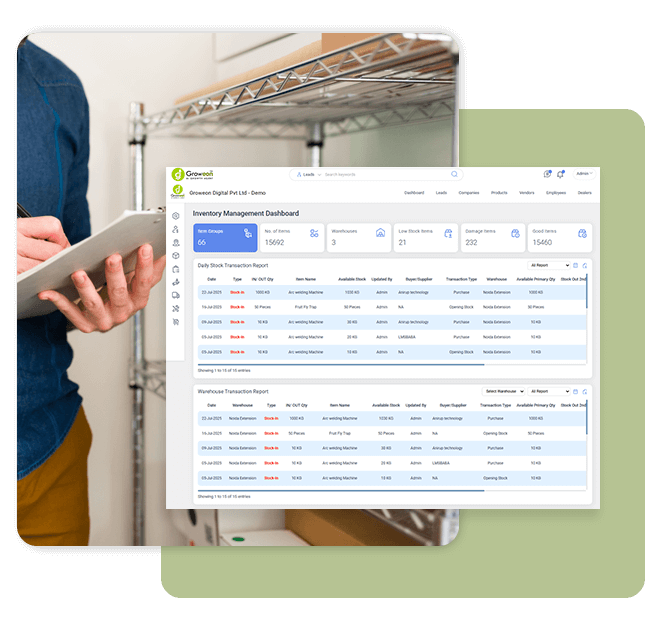

Inventory Management

Manages stock levels, tracks items, ensures efficient inventory control.

-

Dealer Management

Manages dealer workflows, assigns leads, and tracks progress centrally.

-

WhatsApp Business API

WhatsApp CRM integration with bulk messaging, auto notifications, chatbots.

-

IVR Solution

IVR enabled CRM integrates click-to-call, bulk dialling, recording features.

-

Bulk Dialer

Achieves optimum productivity of tele-sales team with auto dialler.

-

- Pricing

- Compliance

- News & Events

- API Integration

- CRM Software

- Industries

- News & Events

- Security

- Blogs

-